Key to Long-Lasting PCB Protection

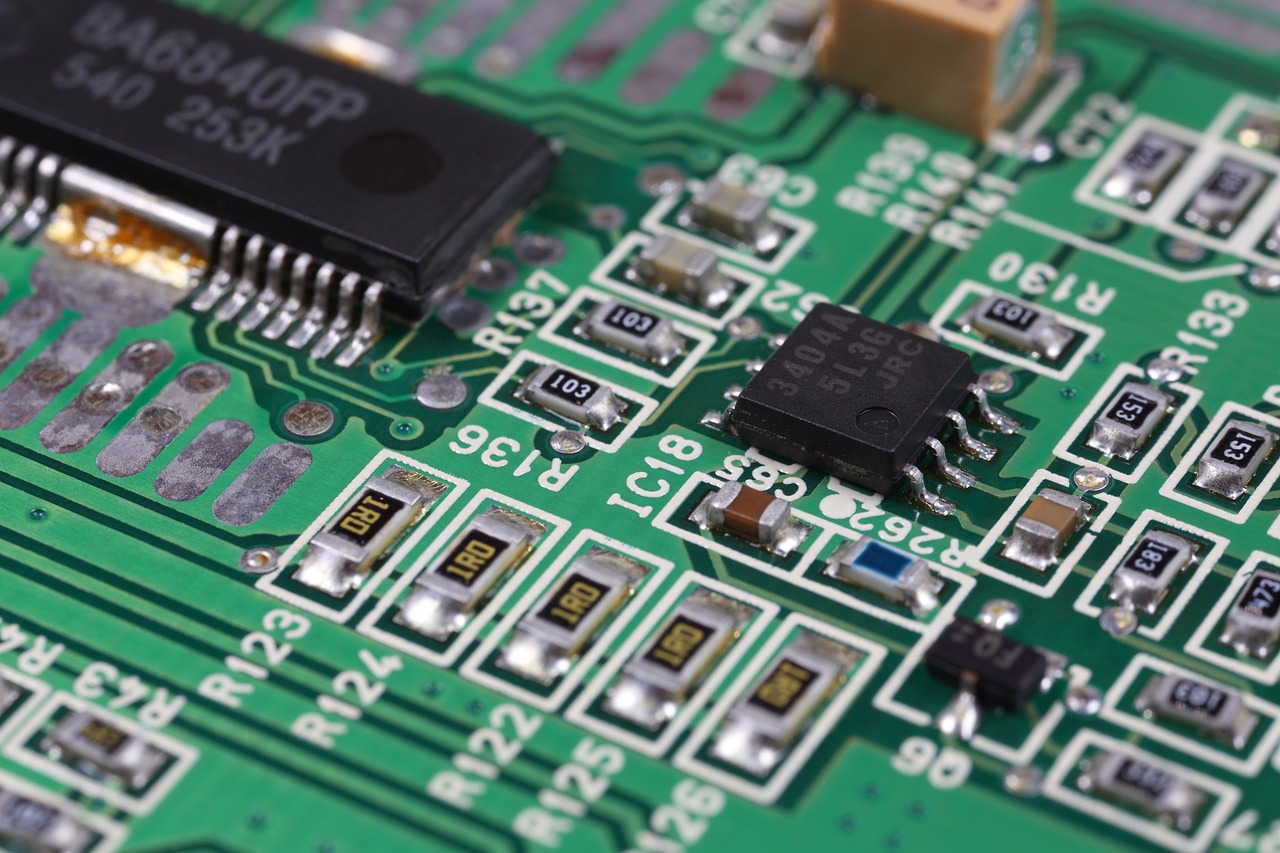

Integrity of PCBs and their components are fundamental to any device’s successful functioning, making their protection even more crucial for success. Without it, devices may become vulnerable to malfunction or even fail altogether due to various environmental conditions like moisture, dust and debris accumulation, electrical issues, mechanical stress or extreme temperatures compromising functionality of a board. By understanding basic principles of PCB protection you can ensure your products remain unaffected by such hazards as moisture intrusion and dust build-up; you’ll ensure they will withstand such environments with confidence.

Moisture damage to printed circuit boards, for instance, can corrode their metal layers and result in less-than-effective conductive traces or even complete board failure. Conformal coatings offer a great solution against this threat as they encase PCBs to shield them from moisture, dust and other potential contaminants.

Key to Optimal Performance

Integrity of a PCB is of critical importance to its components’ proper operation, with vias serving as conduits of signals and power between different layers of a circuit board. Via protection can prevent electrical problems, mechanical stress, extreme temperatures, and electrical interference from damaging them and jeopardizing PCB integrity. Antistatic packaging, conductive trays and other protective tools may provide adequate via protection; additionally proper storage and handling practices help minimize risks by cushioned packaging, secure transportation, and avoiding rough handling practices – among others – are effective means for offering complete via protection for PCB components to function optimally.

Key to Cost-Effectiveness

Optimizing PCB performance and longevity can yield considerable cost savings for businesses that rely on expensive components. Employing protective coatings, secure packaging solutions, and other storage options to reduce structural compromises that might necessitate repairs or replacement costs can save companies both time and money in repairs or replacement expenses.

Conformal coatings provide PCBs with protection from moisture that could corrode their conductive traces and cause electrical shorts, dust and other contaminants, ESD damage as well as cushioned packaging, adequate handling practices during assembly processes or transportation, climate controlled storage environments that protect from extreme conditions which might accelerate aging or deterioration, repairs and maintenance expenses, ultimately decreasing production costs and downtime.