Some flexible resins tend to absorb liquid after printing, so try minimizing contact time between printed parts and liquids such as IPA or water, then thoroughly drying your parts before post-curing.

Proper curing of prints improves both mechanical properties and visual appearance of final parts. Check your prints for signs of tacky spots or uneven UV exposure to ensure the best outcome.

Getting Started

As with any 3D printing project, finding the optimal settings for a resin printer requires some trial-and-error. While it may be tempting to go by what others are suggesting on Facebook groups or elsewhere, finding your ideal settings requires exploring which models and conditions you can control personally.

Temperature and resin curing speeds can have an enormous impact on curing speed – warm rooms and higher temperatures usually result in faster curing times; colder environments require extended exposure times. Furthermore, complex prints may take more time to fully cure than smaller prints due to exposure time considerations.

Uncured prints will often feel tacky and snap easily if handled roughly; to enhance physical properties and visual appeal of prints properly cured by UV radiation exposure time guidelines from manufacturers, it’s crucial that UV exposure times be strictly adhered to.

Keep in mind that cleaning up after printing can be a messy endeavor, but you can make the task less cumbersome by printing a vat dripping holder to help hold printed objects while you drain excess resin into a trashcan or water jug. Make sure to wear proper safety gear such as gloves and goggles during this process.

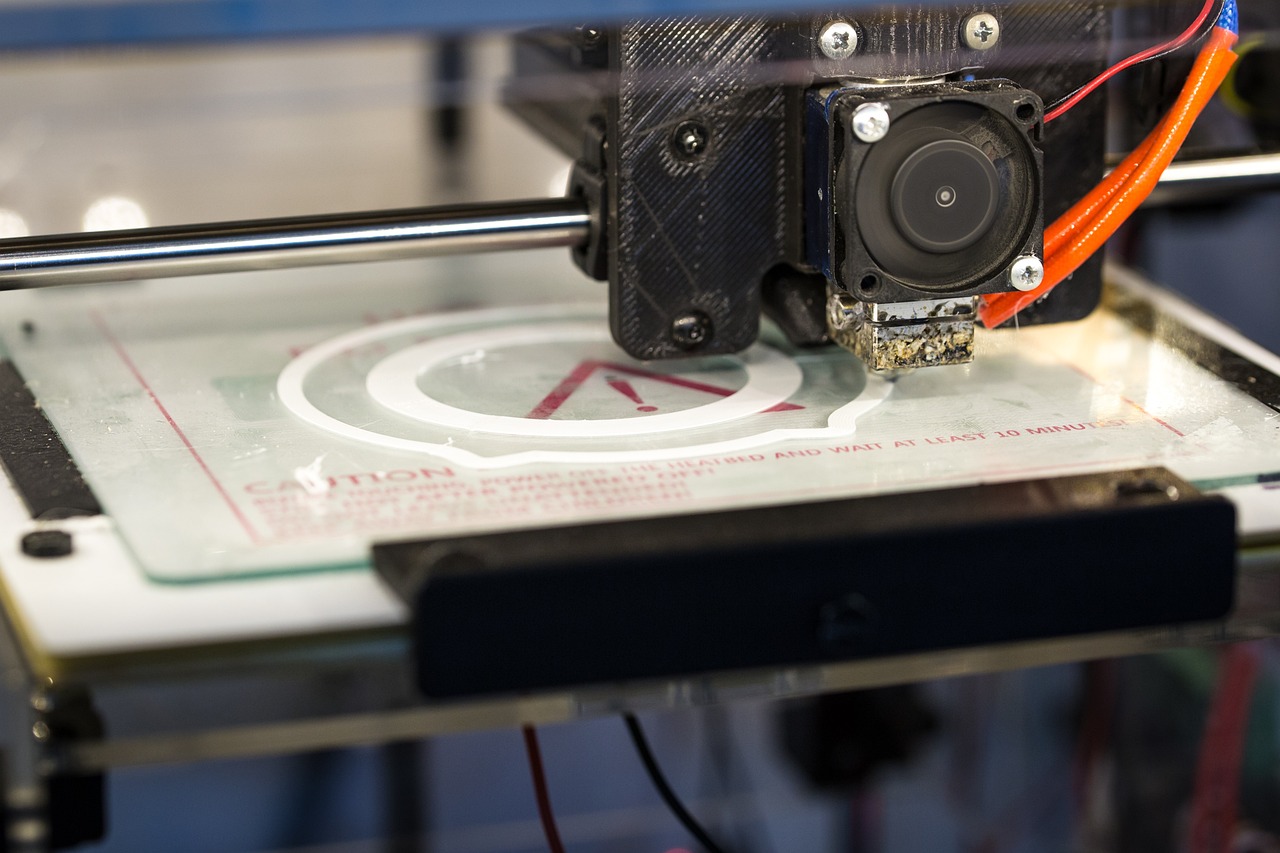

Setting Up the Printer

After printing, resin must be washed, dried and UV cured – an integral step that ensures photopolymers achieve their ideal properties and enhance any print’s aesthetics and functionality. Mastering this post-print step can further elevate any artwork’s visuals and functionality.

As part of washing a printed object, start by filling a tub large enough for the print with water and isopropyl alcohol in a mixture that includes gloves and safety glasses for safety as uncured resin is toxic and may cause skin rashes. A wash and cure station may help speed up this process if you print many prints.

Curing times vary based on factors like resin type, print size and complexity, curing light used and resin flexibility/toughness requirements. A good way to estimate curing times accurately is to follow manufacturer recommendations which can usually be found within technical details for the product in question.

Once the resin has been washed and drained, it’s essential to closely inspect it for signs of tackiness. If any sticky patches remain after curing for sufficient time has passed. Inspect your print from multiple angles so all areas have received sufficient light exposure.

Printing

As soon as your print has finished printing it must be cured – this involves exposing it to UV light that hardens its resin into solid form. A curing station can often do this but direct sunlight or your printers UV light can also achieve this task. Depending on its brand and temperature and humidity conditions, curing may take anywhere between several hours and several days for proper curing results.

Once a print has set up, it can be safely removed from its printer and taken care of using flush cutters if there are any remaining support structures, before being sanded to smooth out any scars and remove scars in its finish.

As part of the curing process, there may be some shrinkage due to cross-linking of photopolymer networks; this is normal and taken into account by PreForm software used to prepare print files for printing.

Care must be taken when handling prints as they can be fragile and delicate. Make sure that they have been fully cleaned and cured prior to handling; this will significantly extend their longevity.

When printing with resin, it is crucial to abide by the print guidelines and curing times specified by your printer manufacturer. Any attempt at speeding up this process through changing temperature settings or other means will likely produce prints which have either undercured or over-cured too quickly, resulting in prints unfit for display.

Curing

Once a print is complete, it needs to be cured in order for all its layers to solidify correctly. Curing is an integral step with any 3D printer but especially resin ones; placing your print into a curing station that rotates it under UV light until all layers have solidified is required for curing – though this process takes some time depending on its type, size, and any added details.

Once a part is completely cured, it’s ready for additional processes like painting or bonding. At this stage it should be handled carefully, as its delicate structure could break easily if handled roughly.

Omitting this step may save time or money, but it is not recommended. Resin can be harmful if it comes in contact with skin; additionally, uncured prints will weaken with time due to ambient lighting, potentially stressing joints or messing with coatings.

For optimal print cleaning, an ultrasonic bath filled with isopropyl alcohol should be used for 5-10 minutes to dissolve any uncured resin and ensure all green parts of the print are completely cleaned before they undergo their final curing stage.